eNPure...Your Single Source Solution for:

Reverse Osmosis Iron Fouling/Scalant Control

eNPure's AS-156 inhibits scale deposition and biological fouling in Reverse Osmosis feed waters containing high levels of soluable iron (Fe+2). Increase Reverse Osmosis recovery rates, decrease

membrane cleanings, and membrane replacements with AS-156.

APPLICATIONS

- Surface waters with variable turbidity

- Ground waters with high fouling tendencies

When ferrous iron is present in

source water, it promotes biological

fouling and inorganic scaling of

reverse osmosis membranes.

Iron inhibits the performance of

most anti-scalants, which causes

increased dosing levels to prevent

the precipitation of calcium and

magnesium salts.

The adverse effects are decreased

reverse osmosis recovery rates,

increased dosing amounts of

anti-scalant, and more frequent

membrane cleanings and

replacements.

DESIGNED FOR FEED WATER WITH MODERATE LEVELS

OF IRON UP TO 5 PPM Fe+2 (FERROUS IRON)

CONTROLS CaCO3, CaSO4, BaSO4, SrSO2,

AND SILICATE SCALE

DISPERSES METAL OXIDES AND INORGANIC

PARTICULATES LIKE SILT AND CLAY

STABILIZES METAL IONS TO PREVENT METAL HYDROXIDE,

METAL PHOSPHATE, AND METAL SILICATE PRECIPITATION

INCREASES REVERSE OSMOSIS RECOVERY RATES

DECREASE AMOUNT OF MEMBRANE CLEANINGS

AND MEMBRANE REPLACEMENTS

INCREASED REVERSE OSMOSIS UPTIME

LOWER DOSING LEVELS THAN

OTHER ANTI-SCALANTS

eNPure's water treatment experts can help you prevent fouling and scaling in Reverse Osmosis Systems utilizing advanced and proprietary process design and engineering.

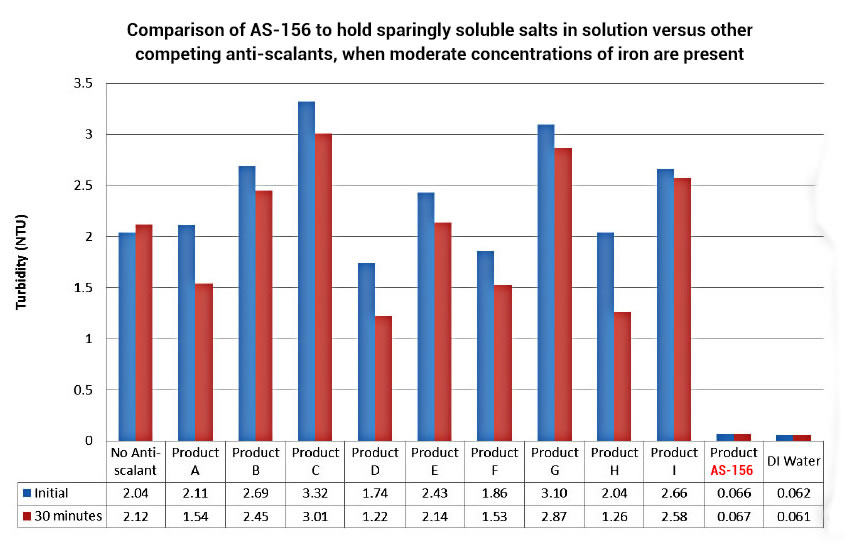

The below graph is from a case study comparing anti-scalants available in the market, which was performed to prove the impact of ferrous ion oxidation on silica scaling in reverse osmosis systems. It shows that Enpure's AS-156 prevents almost all precipitation which causes scaling in reverse osmosis systems.